0 items - $0.00

- No products in the cart.

|

Product Solutions of Creative Material Technologies, Ltd. |

|

Products labeled “Polyurea Hybrid” can range anywhere from a 99% Polyurea / 1% polyurethane mix to a 1% Polyurea / 99% Polyurethane mix. At CMT, we believe you should be confident in your materials, and we offer both Polyurea Hybrids and 100% Pure Polyureas.

Zero VOC’S does not mean “No Solvents”. True 100% solids coating systems, while being more expensive per gallon, have a low enough viscosity to be sprayed without the use of any solvent.

CMT offers Zero VOC Polyureas

All solids are not created equal. Some manufacturers add fillers, additives, and other non-resin components (to increase their margins), reducing the performance properties of the product. Resins build physical properties and maximize crosslinking, while fillers typically only increase volume. CMT’s products are engineered to be the best quality on the market; therefore we generally do not use fillers unless your application or custom application requires them.

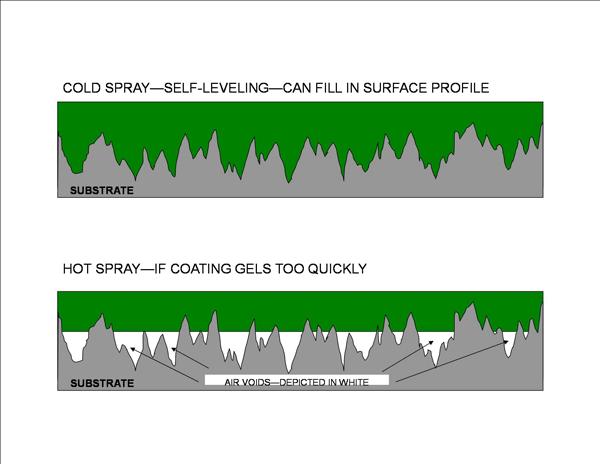

The shorter the open time, the faster the coating gels and is less able to flow. Of course, everyone wants a product that cures quickly, but if it gels too quickly to conform to the surface profile (wetting out), you risk catastrophic adhesion failure.

CMT offers a variety of working times for your application-specific needs.

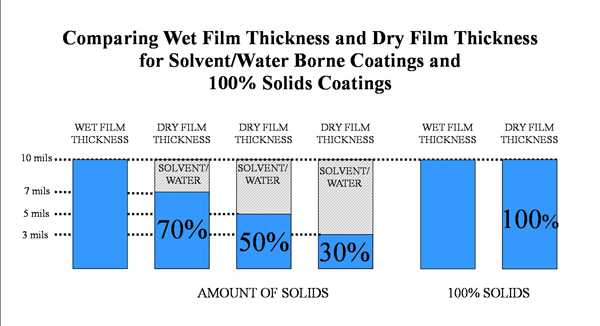

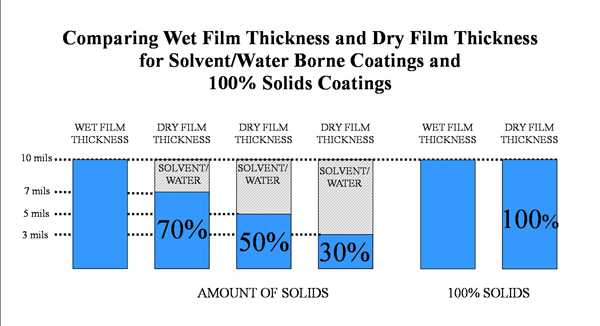

Coatings containing solvents or water are inherently more porous than 100% solids coatings systems. Further, the dry film thickness (after cure) is much less than the thickness applied when wet. To ensure you get the highest dry film coating thickness for your money, CMT has engineered Polyureas with no Solvents.

Coatings containing solvents or water are inherently more porous than 100% solids coatings systems. This means the dry film thickness (after cure) is much less than the thickness applied when wet. To ensure you get the highest dry film coating thickness for your money, CMT has engineered Polyureas with no Solvents.

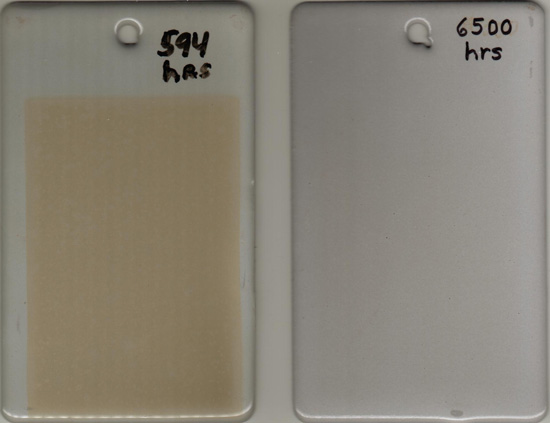

Some products from other suppliers are labeled “Aliphatic”, but are actually only 51% aliphatic (and 49% aromatic). Since these products are not 100% Aliphatic, they are not UV stable and will deteriorate and change color over time (see image below). CMT knows that only 100% aliphatic polyureas are truly UV Stable, and we engineer our products accordingly.

Below are equivalent exposure results through the use of QUV accelerated weathering equipment. (1000 hours of accelerated weathering is roughly equivalent to 1 year of outdoor exposure.) These samples are a 50 Mil Coating deposited by a High Pressure Spray System on a metal test panel.

Both test panels were originally coated with a standard grey color (appears at the top of the panel). The exposed area is the rectangular below where the hours are written.

| AROMATIC

|

ALIPHATIC

|

| Color degredation (as evidenced by green tint discoloration) in under 6 months of exposure

|

Still Grey after 6.5 years exposure

|

Coatings with NO solvents of any kind by design have the capacity of exhibiting the highest crosslink density, but will vary by formula. CMT offers 100% Solids Polyureas.

Crosslink Density is a critical issue to understand, since it is directly related to performance properties of a coating system.

Visualizing Crosslink Density:

Crosslink Density can be thought of as the number of resin molecules bonded together in a specific area. For instance, chain mail has a much higher crosslink density than a chain link fence, as pictured below.

| CHAIN MAIL

|

VS. | CHAIN LINK FENCE

|

|

|

|

Factors that affect safety include not only chemistry and free monomer, but also particle size and mist resulting from the polyurea application.

CMT offers safer chemistry with safer application methods

High performance coatings should be purchased based upon the application’s requirements. While some companies have a “one size fits all” approach to product sales, CMT knows that different problems require different solutions.

CMT listens and spends time with our customers to understand their real needs, and if appropriate, CMT develops a custom solution where no solution currently exists. CMT considers clients to be “business partners”, and not just customers.

See Previous:

Polyurea InstallationSee Next:

CMT Green Standards DYNA-PRIME™ N-23 Water Chasing® Primerby Daniel

DYNA-PRIME™ N-23 Water Chasing® Primerby Daniel DYNA-PUR™ 7416BL Brushable Polyureaby Alex

DYNA-PUR™ 7416BL Brushable Polyureaby Alex Patch 'N Go™ (8010-TR)by David

Patch 'N Go™ (8010-TR)by David